Non--standard HSK Tool holders for CNC

Get Latest Price| Payment Type: | T/T,Money Gram,Western Union |

| Incoterm: | FOB |

| Transportation: | Ocean,Air, E-package |

| Port: | Qingdao,Shenzhen |

Select Language

| Payment Type: | T/T,Money Gram,Western Union |

| Incoterm: | FOB |

| Transportation: | Ocean,Air, E-package |

| Port: | Qingdao,Shenzhen |

Brand: Chongde

Material: 20CrMnTi

Application: Metal

Run Out: 0.005mm 0.008mm

Carbon Depth: >0.8mm

HARDNESS: 58±2HRC

We are specialized in researching,producing and developing many kinds of collets,CNC Machine Tool Holder, SK Nuts,SK Spanners,machine vises,fasteners etc. With high quality and full varieties.

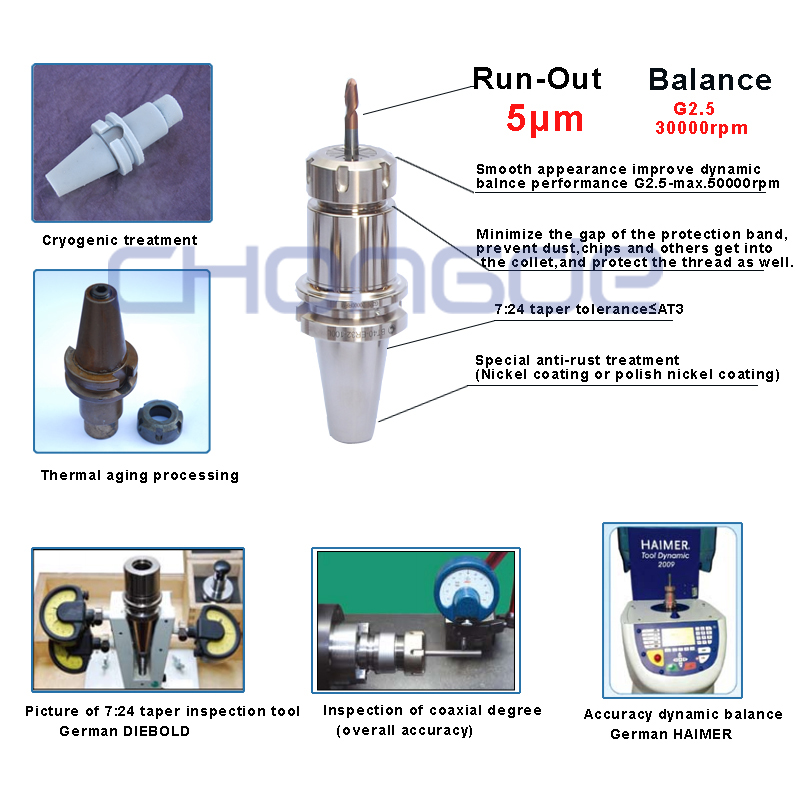

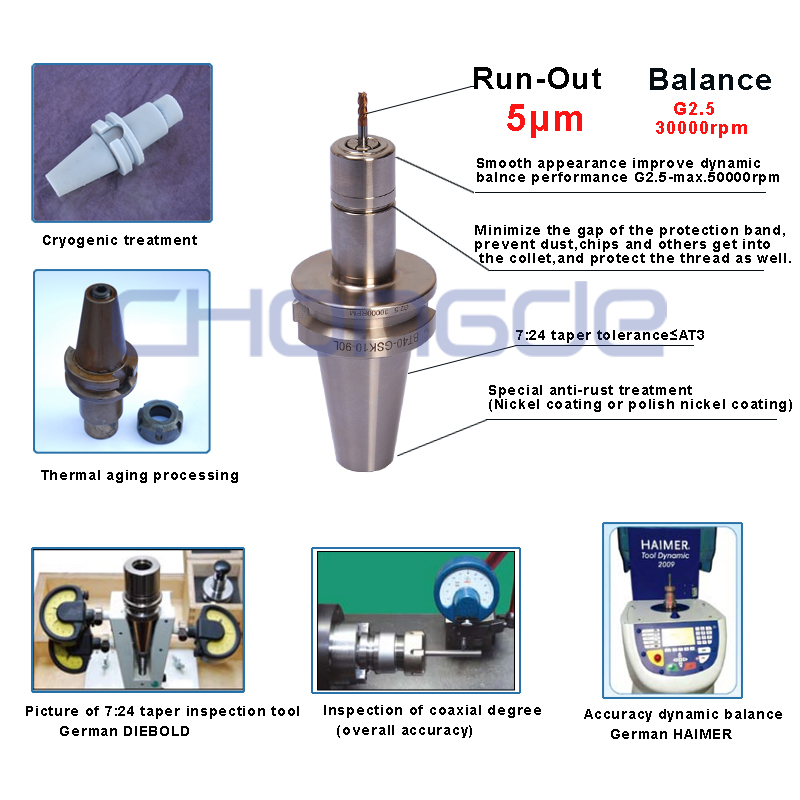

HSK Tool Holders for mechanical spindle and cutting tool and other accessory tool connection. Is a simple, popular spindle shank connection standard, mainly HSK32E HSK40E HSK50E... Etc.. Mold industry, and high-speed engraving machine, used more. Comprehensive inspection way of chuck 1.7:24 taper precision≤AT3 and part of the standard size are tested by Diebold standard inspection tools which made in Germany. 2.Surface of the clamping inner hole is grinding by high speed inner-aperture grinder,and inspect by standard pneumatic measurement instrument;the big end contact area rate is above 90%. 3.Run out of the inside shank cone≤0.002(The length of the shank 100L); 4.Coaxiality 5U:Shank run out ≤0.002;Equip collet ≤0.005,The highest comprehensive run out point is no more than 0.005mm; 5.Dynamic balance:We can do G2.5 30000~50000rpm according to clients' demands. 6.Shank thread is inspected with 4h level thread ring gauge, and the nut is inspected with 4H level thread plug gauge,the quality guaranteed; Hsk Tool Holders for mechanical spindle and cutting tool and other accessory tool connection. Is a simple, popular spindle shank connection standard, Mold industry, and high-speed engraving machine, used more. We are specialized in researching,producing and developing many kinds of collets,CNC Machine Tool Holder, sk nuts,sk spanners,machine vises,fasteners etc. With high quality and full varieties. Products advantages 1.High speed chuck appearence:coating and polishing a.The roughness of surface has been reduced to improve the stability of the precision.The bumpy surface get smooth after polishing,the pore,scratch and other flaw has been filled so as to improve the endurance. b.The polishing doesn't influence precision.The coating is even and chemical fluid spitting degree is almost 100%.It can prevent the spindle from abrasion and don't influence precision. c.The endurance has been improved.The abrasion of nickel is strong,it has a good effects of anti-rust in different medium environment. d.The appearance is smooth and bright,feels comfortable. 2.Overall nickel coating,including inside and outside cone,even if you don't take any anti-rust actions,it will not rust either,don't influence processing precision and spindle. 3.The products without coating is easy to rust,reduce processing precision,influence the chuck and spindle. 4.If the shank rust,insert run-out will enlarge to 0.01-0.02. 5.-196℃ cryogenic treatment and thermal aging processing.

Surface roughness is reduced ,precision stability improved.

The Collet Chuck surface uneven texture,after polishing,the surface roughness can be leveling ,smooth and shining surface.At the same time filling surface pores scratches and other surface defects,thus improve the fatigue strength,corrosion resistance increase.

Don't influence precision.

Chuck surface is coated ,the layer is evenly ,Chemical plating solution dispersion degree of almost 100%,nickel layer is thin ,thickness is about 3u-5u,this special coating can reduce Spindle abnormal wear and tear ,Don't influence precision.

Anti-rust,anti-corrosion,durability better.

Coating adhesiion strong,enhance hardness,and anti-rust better in different surroundings,such as acid,alkali,ammonia,salt etc.Overall nickel coating ,including inside and outside cone,even if you do not take any anti-rust actiions ,it will not rust either,don't influence processing precision and spindle .Improve cleanness,precision more stable,surface more smooth,feel more comfortable and appearance nicer.

Our factory

1.Package: plastic boxes and also can pack according to your requests.

2.Delivery time:Sample within 7 days and others 35 days.

I Fast reply

II Favourable price

III High quality products

IV Fast delivery

Ⅴ Good after-sales service

1.Are you factory or Trade Company?

We are industry and trade integration.

2.Could you supply samples?

Yes ,free samples for some products.

3.Where do you export?

The whole world.

4.Could you produce non-standard products?

Yes ,we can .Please supply samples or drawing.

5.What are the shipping ways?

By intemational express,by air ,by sea are all OK.

6.Do you have minimum order quantity?

Conventional Products don't have.The minimum order quantity of non-standard products is 50pcs.

7.What's your delivery time?

Less than 25 days after order confirmed .

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.